For

CommercialSoapDispenserAuto.com

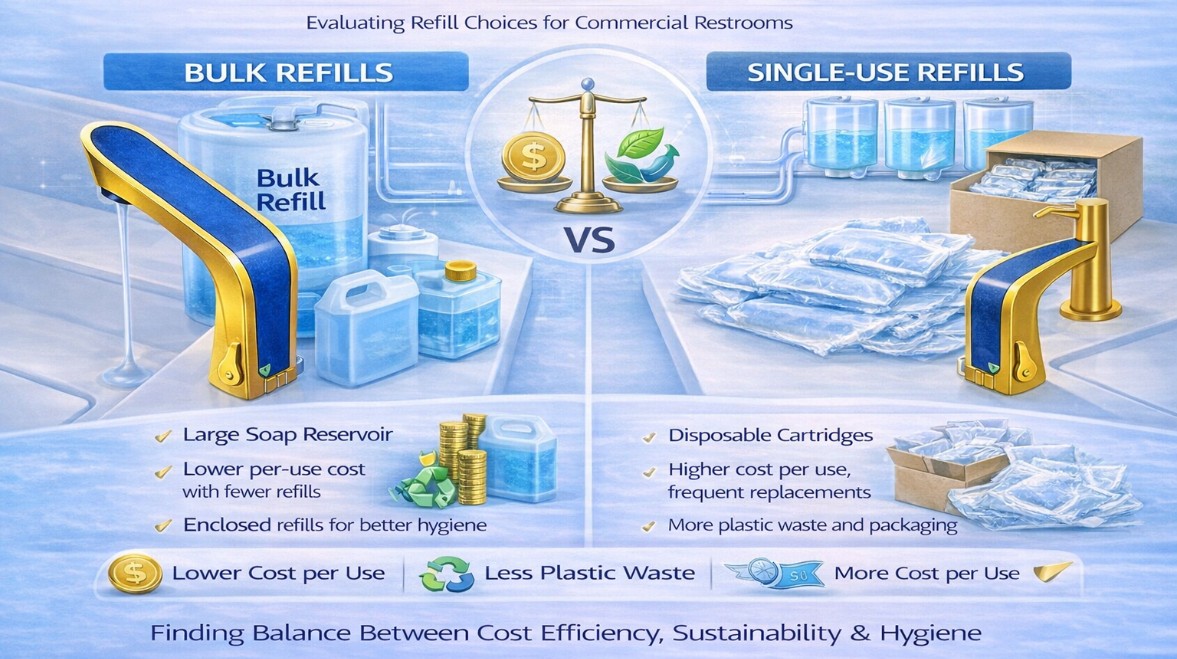

Bulk vs Single-Use Refills: Economics, Sustainability & Hygiene Trade-Offs

Refill strategy is one of the biggest drivers of performance in touch free soap dispensing. The dispenser body might last years, but refills cycle weekly or daily in heavy use restrooms. That means refill format drives labor time, packaging waste, outage risk, and hygiene control.

In AEC work, bulk fill and single use sealed cartridges both have valid applications. The right choice depends on traffic, staffing consistency, contamination risk tolerance, and whether the owner is pursuing frameworks like WELL that explicitly address sealed cartridges for contamination reduction. https://standard.wellcertified.com/v2/nourishment/hand-washing

Working definitions used in this guide

Bulk refill means soap is poured or pumped into a refillable reservoir. This includes top fill, open fill, and some large reservoir systems.

Single use refill means a sealed cartridge or bag is replaced as a unit, typically keyed to a compatible dispenser.

Economics means total cost of ownership including soap cost per dose, labor minutes per refill, downtime events, and parts replacement.

Sustainability means packaging material volume, recyclability, transport impacts, and waste management burden over time.

Hygiene means contamination risk in the soap pathway and how refill practices support safe hand hygiene.

Economics: what actually changes between bulk and sealed refills

Labor time per refill is the first cost driver

Bulk systems can be inexpensive per liter, but they often take longer per service because staff must open, pour, clean spills, and sometimes prime. Sealed cartridges are usually faster and cleaner to change but can carry a higher unit product cost.

A practical way to evaluate is to calculate:

- Minutes per refill event

- Refills per week per dispenser

- Labor cost per hour

- Downtime cost when a unit is empty during peak hours

Even small time differences matter at scale. A site with 80 dispensers and two refill rounds per week can turn a 1 minute difference into more than 2.5 hours of labor weekly.

Downtime and “empty but not obvious” events

Sealed systems often make it easier to standardize inventory and reduce mismatched products. Bulk systems can reduce running out if large reservoirs are used, but only when staff reliably tops up using correct procedures.

Connected monitoring can reduce unnecessary checks and empty events if the owner is ready to manage gateways and response workflows. Large programs like Tork Vision Cleaning describe connected dispensers and reporting for cleaning efficiency and refill planning. https://tork-images.essity.com/images-c5/513/402513/original/tork-tvc-4pagebrochure-0622.pdf

Theft and misuse risk in public restrooms

In unsupervised restrooms, bulk fill units are more vulnerable to misuse, including topping off with unknown liquids or dilution errors. Sealed refills reduce this risk because the product pathway is controlled.

Hygiene trade offs: contamination risk is mostly about refill practice

Bulk refill contamination is a documented issue

Peer reviewed research in Applied and Environmental Microbiology reports that bulk soap refillable dispensers are prone to extrinsic bacterial contamination and quantified bacterial transfer after washing with contaminated soap. https://journals.asm.org/doi/10.1128/aem.02632-10

A separate study focused on food service environments found detectable bacteria in bulk soap samples and concluded that refillable bulk soap dispensers can create public health risk in those contexts. https://www.sciencedirect.com/science/article/pii/S0362028X22084575

What this means for specifications:

- Bulk fill can be appropriate, but only with strict protocol.

- The risk rises when staff turnover is high or training is inconsistent.

WELL pushes sealed cartridges for contamination reduction

WELL v2 Hand Washing includes a contamination reduction pathway that specifies liquid soap in dispensers with disposable and sealed soap cartridges at sink locations. https://standard.wellcertified.com/v2/nourishment/hand-washing

This is one of the clearest examples of a certification framework translating hygiene concern into a specific dispenser and refill approach.

Bulk can still be used safely with the right controls

If bulk refill is selected, add operational requirements:

- No top off policy (do not add new soap into old soap)

- Scheduled reservoir cleaning and drying

- Approved soap list and dilution control

- Documented training for staff and contractors

Sustainability: packaging waste is not the only metric

Packaging volume and waste streams

Bulk refills can reduce packaging per liter when soap is purchased in large containers. Sealed cartridges increase packaging, but they can reduce product waste from spills, overfilling, and contamination driven disposal.

Owners often want a way to compare impacts. EPA’s Waste Reduction Model (WARM) is designed to provide high level comparisons of greenhouse gas impacts and energy factors for different materials management practices and can support waste planning discussions when packaging streams are quantified. https://www.epa.gov/waste-reduction-model

Reuse systems need realistic assumptions

Recent lifecycle assessment literature on reusable versus single use packaging emphasizes that comparisons depend heavily on operational parameters and real world data once a system is in use. This is relevant because refill strategies also depend on how often containers are cleaned, how much product is wasted, and how transport and storage work in practice. https://www.sciencedirect.com/science/article/pii/S0959652625005578

A practical sustainability approach for AEC teams

Instead of assuming bulk is always greener or sealed is always worse, measure:

- Packaging mass per 1,000 dispenses

- Soap waste per refill event (spills, expired product, contaminated product disposal)

- Transport frequency (cases, pallets, storage space)

- End of life handling (recycling availability for cartridges and containers)

How to choose by building type and risk profile

High traffic public restrooms with variable staffing

Examples: transit hubs, malls, stadiums, public parks

Best fit often: sealed refills or locked systems with controlled refills

Reason:

- Better control of soap pathway and refill consistency

- Less chance of contamination from improper top off

- Cleaner and faster refill actions

WELL contamination reduction language can also support owner hygiene narratives if the project is using WELL. https://standard.wellcertified.com/v2/nourishment/hand-washing

Schools and campuses with in house maintenance teams

Best fit can be either, depending on training:

- Bulk can work if staff is stable and protocols are enforced

- Sealed can reduce variability and reduce training burden

Healthcare and high accountability facilities

Best fit often: sealed cartridges and standardized platforms, aligned with hand hygiene programs

CDC emphasizes that hand hygiene includes washing with water and soap or using alcohol based hand rub, depending on context. https://www.cdc.gov/clean-hands/hcp/clinical-safety/index.html

In these environments, contamination control and predictable availability often outweigh packaging optimization.

Low traffic restrooms and small offices

Either approach can work. If refills are infrequent, sealed refills can reduce mess and simplify inventory, while bulk may reduce unit costs if a central supply already exists.

Specification language that prevents the common failures

A) For bulk refill systems

Include in Division 10 or O and M requirements:

- No top off policy

- Reservoir cleaning interval and method

- Approved soap chemistry and dilution method

- Locking cover and controlled access in public areas

- Commissioning check for dose consistency and no drips

Support your rationale with hygiene research references when needed:

https://journals.asm.org/doi/10.1128/aem.02632-10

B) For sealed cartridge systems

Include:

- Cartridge type and expected doses per cartridge

- Lead time and storage requirements for the refill supply chain

- Disposal and recycling approach for the cartridge material if available

- Standard keying and compatibility rules to prevent mix and match errors

C) For both systems

Include measurable performance:

- Dose per activation (mL) and tolerances

- Single activation lockout behavior if adjustable

- Foam versus liquid compatibility

Category pages for comparing system families

These category pages help AEC teams compare mounting types, refill architectures, and coordinated washroom systems:

Bobrick soap dispensers and faucets category

https://www.bobrick.com/product-catalog/categories/soap-dispensers-faucets/

Bradley soap dispensers category

https://www.bradleycorp.com/product-category/soap-dispenser

ASI soap dispensers category

https://americanspecialties.com/product_category/soap-dispensers/

Connected monitoring context example

https://www.torkusa.com/tork-vision-cleaning

Conclusion

Bulk and single use refills are not a simple cost versus sustainability argument. Bulk systems can reduce packaging and product cost per liter, but they require stable staffing and strict hygiene protocol to avoid contamination risk documented in peer reviewed studies. Sealed refills typically improve hygiene control and refill consistency and are directly supported by WELL contamination reduction language. The best AEC approach is to select a refill strategy based on traffic, staffing reliability, and hygiene risk, then specify measurable dose performance and include clear operational procedures so the system performs the same way after handover as it did on opening day. https://standard.wellcertified.com/v2/nourishment/hand-washing

Supporting References

WELL v2 Hand Washing feature library, sealed cartridge language

https://standard.wellcertified.com/v2/nourishment/hand-washing

Peer reviewed bulk soap contamination study, Applied and Environmental Microbiology

https://journals.asm.org/doi/10.1128/aem.02632-10

Food service bulk soap contamination study, Food Control

https://www.sciencedirect.com/science/article/pii/S0362028X22084575

CDC hand hygiene clinical safety guidance

https://www.cdc.gov/clean-hands/hcp/clinical-safety/index.html

EPA Waste Reduction Model overview and documentation

https://www.epa.gov/waste-reduction-model

https://www.epa.gov/waste-reduction-model/documentation-waste-reduction-model

Lifecycle assessment discussion relevant to refillable versus single use packaging comparisons

https://www.sciencedirect.com/science/article/pii/S0959652625005578

Example connected cleaning and refill analytics brochure

https://tork-images.essity.com/images-c5/513/402513/original/tork-tvc-4pagebrochure-0622.pdf

Category pages for dispenser system comparison

https://www.bobrick.com/product-catalog/categories/soap-dispensers-faucets/

https://www.bradleycorp.com/product-category/soap-dispenser

https://americanspecialties.com/product_category/soap-dispensers/

No responses yet