For

CommercialSoapDispenserAuto.com

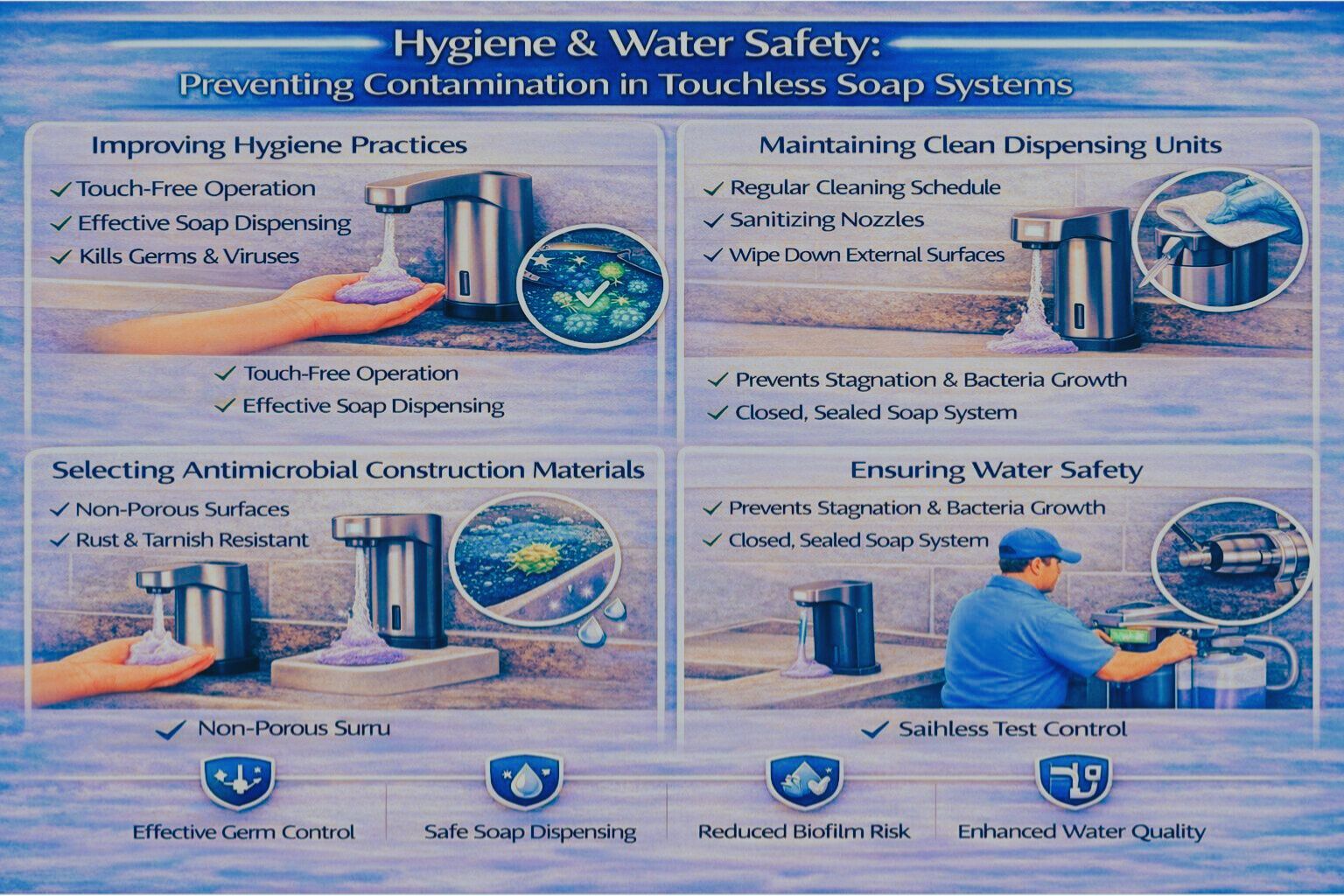

Hygiene and Water Safety: Preventing Contamination in Touchless Soap Systems

Touchless soap systems are often installed to improve hygiene, reduce touch points, and streamline restroom maintenance. In public restrooms, schools, hospitals, airports, and stadiums, these systems also introduce a new risk pathway if refill practices, reservoir design, and cleaning protocols are not controlled.

Contamination problems rarely come from the sensor itself. They come from how soap is stored, refilled, and exposed to the environment. In high traffic restrooms, a single poor refill practice can affect dozens of users before anyone notices.

This guide focuses on contamination prevention for commercial touchless soap dispensers, including sealed cartridges, bulk refill, and multi-feed systems, with practical steps AEC teams can document and facilities teams can follow.

Working definition

In this article:

Touchless soap system means any soap dispenser that dispenses without direct hand contact, typically using an infrared sensor and an internal pump.

Contamination means unwanted microbial presence introduced into the soap product, the reservoir, the nozzle, or internal wetted components, usually through refilling practices, backflow, or biofilm buildup.

Water safety refers to reducing hygiene risks linked to rinse behavior and wet surfaces in the sink zone, including preventing soap residue and splash from turning into a maintenance and cleanliness problem.

Why contamination happens in refillable soap systems

Touchless operation reduces contact at the dispenser surface, but the soap pathway can still become contaminated. The highest risk conditions are commonly linked to open refillable bulk reservoirs and topping off practices.

A peer reviewed study in Applied and Environmental Microbiology reported that bulk soap refillable dispensers are prone to extrinsic bacterial contamination and evaluated hand contamination and transfer after washing with contaminated bulk soap.

A separate field study surveyed the microbial quality of open refillable bulk soap in food service establishments and discussed how soap formulation and facility type can influence microbial quality.

These findings matter because they shift the specification question from “touchless or not” to “how is the soap stored and refilled.”

System tiers: sealed refills vs bulk fill vs multi-feed top fill

Sealed cartridge and sealed bag systems

Manufacturers design sealed refills to reduce product exposure during changeouts; they factory-seal the refill, install it as a single unit, and replace it entirely when it runs empty.

Why sealed refills tend to reduce contamination risk:

- Soap is not poured into an open reservoir

- Topping off is eliminated

- The wetted path can be refreshed depending on design

- Changeout is faster and more consistent across staff teams

Best fit environments:

- Healthcare

- Education campuses

- Airports and transit facilities

- Buildings with outsourced janitorial teams and high staff turnover

Reference system example:

https://www.gojo.com/en/product-catalog/productdetail?sku=2730-12

Bulk fill reservoirs

Bulk fill systems involve refilling a dispenser reservoir from a larger container. These systems can be economical, but hygiene performance depends heavily on procedures.

Contamination drivers in bulk fill:

- Topping off without cleaning the reservoir

- Contaminated refill funnels and containers

- Residual soap film that supports biofilm growth

- Inconsistent cleaning schedules and staff practices

Bulk fill can perform well only when an operations protocol is clear and enforced. Without that, bulk fill is the refill method most associated with contamination concerns in the research literature.

Multi-feed and top-fill systems

Multi-feed systems supply multiple dispensers from one reservoir, often through a top-fill station. These systems can reduce labor and keep dispensers from going empty along long sink runs.

They also concentrate risk. If the central reservoir becomes contaminated, multiple dispensers can be affected.

Multi-feed examples:

https://www.bradleycorp.com/product/multi-feed-soap-system

https://americanspecialties.com/product/ez-fill-top-fill-multi-feed-kit-0390/

Best fit environments:

- Stadiums and arenas

- Convention centers

- Airports

- Large campuses with long sink runs and dedicated maintenance staff

Key requirement:

A multi-feed reservoir needs the same cleaning discipline as a bulk fill reservoir, plus better labeling, service access, and documentation.

Contamination control: what AEC teams can specify and document

1) Prohibit topping off in bulk refill systems

The single most effective policy in refillable systems is a no topping off rule.

Best practice approach:

- Only refill after reservoir is emptied

- Clean reservoir and wetted parts before refilling

- Use a documented procedure and log

This reduces the chance that old soap remains as a contaminated base.

Support evidence:

https://journals.asm.org/doi/10.1128/AEM.02632-10

https://www.sciencedirect.com/science/article/pii/S0362028X22084575

2) Require a cleaning procedure for the reservoir and nozzle

Touchless dispensers can develop soap film and residue at:

- Nozzle tip

- Pump check valves

- Reservoir walls

- Tubing connectors in multi-feed systems

Specification detail that helps:

- Include a cleaning interval in the closeout manual

- Define allowable cleaners for the reservoir and sensor window

- Require nozzle access without special tools when possible

If the reservoir cannot be cleaned easily, it will not be cleaned.

3) Control the refill tools and refill path

Contamination often enters through refill tools, not the dispenser.

Requirements to reduce risk:

- No shared open funnels stored in janitor closets

- Use dedicated refill tools that can be cleaned and dried

- Keep bulk soap containers closed when not in use

- Use closed transfer methods when available

If a facility uses bulk soap, the refill workflow should be treated like any other hygiene sensitive process.

4) Verify soap compatibility and avoid unapproved substitutions

Soap chemistry affects both performance and residue.

Common issues:

- Thick soaps can clog valves and create buildup

- Foaming soaps may leave different residue patterns than liquid soaps

- Mixing soap types can destabilize performance and cleaning effectiveness

AEC documentation checklist:

- Specify soap type by location (foam vs liquid)

- Require dispenser compatibility with the intended soap type

- If the owner wants flexibility, require a dispenser designed for viscosity variation and provide maintenance notes

Water safety in the sink zone: splash, rinse behavior, and recontamination

Hygiene is also influenced by how the sink zone handles water and rinsing.

CDC notes that clean, running water should be used for handwashing rather than standing water, since hands can become recontaminated if rinsed in a basin of standing water.

Design impacts for AEC teams:

- Avoid layouts that encourage users to rinse in standing water conditions

- Coordinate faucet placement and basin geometry to reduce splash on dispenser housings and sensor windows

- Keep soap dispensing over the basin to reduce dripping on counters and floors

Reference:

https://www.cdc.gov/clean-hands/data-research/facts-stats/index.html

Foam vs liquid: hygiene and maintenance tradeoffs

Foam soap

Typical advantages in commercial restrooms:

- Often perceived as spreading quickly across hands

- Can reduce product consumption in some facilities depending on dose setting

Typical maintenance risks:

- Foam screens and nozzle tips can clog with dried residue

- Nozzle cleaning becomes more important

Liquid soap

Typical advantages:

- Simpler flow path in many pumps

- Familiar performance in many public restrooms

Typical maintenance risks:

- More visible dripping if placement is poor

- Thick formulations may stress pumps not designed for viscosity

The contamination control priority is consistent across both:

Use a refill method and cleaning protocol that prevents soap film buildup and limits exposure during refills.

Field signs that a touchless soap system may be compromised

Common warning signs facilities teams should treat as actionable:

- Soap appears separated, off-color, or has unusual odor

- Dispense becomes inconsistent, sputtering, or unusually runny

- Frequent nozzle clogging and repeated cleaning needed

- Reservoir walls show visible film or buildup

- Multiple dispensers show the same failure pattern in a multi-feed system

These symptoms do not confirm contamination, but they are the right trigger for cleaning, flushing, and checking refill practices.

Selection checklist for AEC teams

Step 1: Match refill strategy to the building type

- Healthcare and high sensitivity sites: sealed refills preferred

- Large public venues: multi-feed can be effective with strong cleaning protocol

- Low to moderate traffic: sealed refills or controlled bulk refill based on staffing

Step 2: Require documented refill and cleaning procedures

- No topping off

- Cleaning interval

- Approved cleaners

- Training and signage for maintenance staff

Step 3: Design for service access

- Reservoir and nozzle must be reachable

- Sensor windows must be cleanable without damage

- Multi-feed tubing and reservoir access must be documented

Step 4: Coordinate sink zone splash control

- Dispenser location over basin

- Avoid placing dispensers in the primary splash zone

- Coordinate faucet outlet and basin depth to reduce overspray

Example basis of design references

Peer reviewed contamination evidence:

https://journals.asm.org/doi/10.1128/AEM.02632-10

https://www.sciencedirect.com/science/article/pii/S0362028X22084575

CDC hand hygiene and rinse guidance:

https://www.cdc.gov/clean-hands/hcp/clinical-safety/index.html

https://www.cdc.gov/clean-hands/data-research/facts-stats/index.html

Multi-feed and top-fill systems:

https://www.bradleycorp.com/product/multi-feed-soap-system

https://americanspecialties.com/product/ez-fill-top-fill-multi-feed-kit-0390/

Sealed refill system example:

https://www.gojo.com/en/product-catalog/productdetail?sku=2730-12

Conclusion

Preventing contamination in touchless soap systems depends more on refill design and maintenance protocol than on sensor technology. Sealed refills reduce exposure and eliminate topping off. Bulk fill and multi-feed systems can work in commercial restrooms, but they require a clear no topping off policy, routine reservoir cleaning, controlled refill tools, and documented procedures delivered at closeout.

For AEC teams, the most reliable strategy is to select the refill method based on building risk profile and staffing capacity, then standardize the refill workflow as part of the restroom accessory package so hygiene performance stays consistent after occupancy.

Supporting References

https://journals.asm.org/doi/10.1128/AEM.02632-10

https://www.sciencedirect.com/science/article/pii/S0362028X22084575

https://www.cdc.gov/clean-hands/hcp/clinical-safety/index.html

https://www.cdc.gov/clean-hands/data-research/facts-stats/index.html

https://www.bradleycorp.com/product/multi-feed-soap-system

https://americanspecialties.com/product/ez-fill-top-fill-multi-feed-kit-0390/

https://www.gojo.com/en/product-catalog/productdetail?sku=2730-12

No responses yet