For

CommercialSoapDispenserAuto.com

Soap/Dispenser Specification: Selecting Flow Rate, Dispense Time, and Replenishment Interval

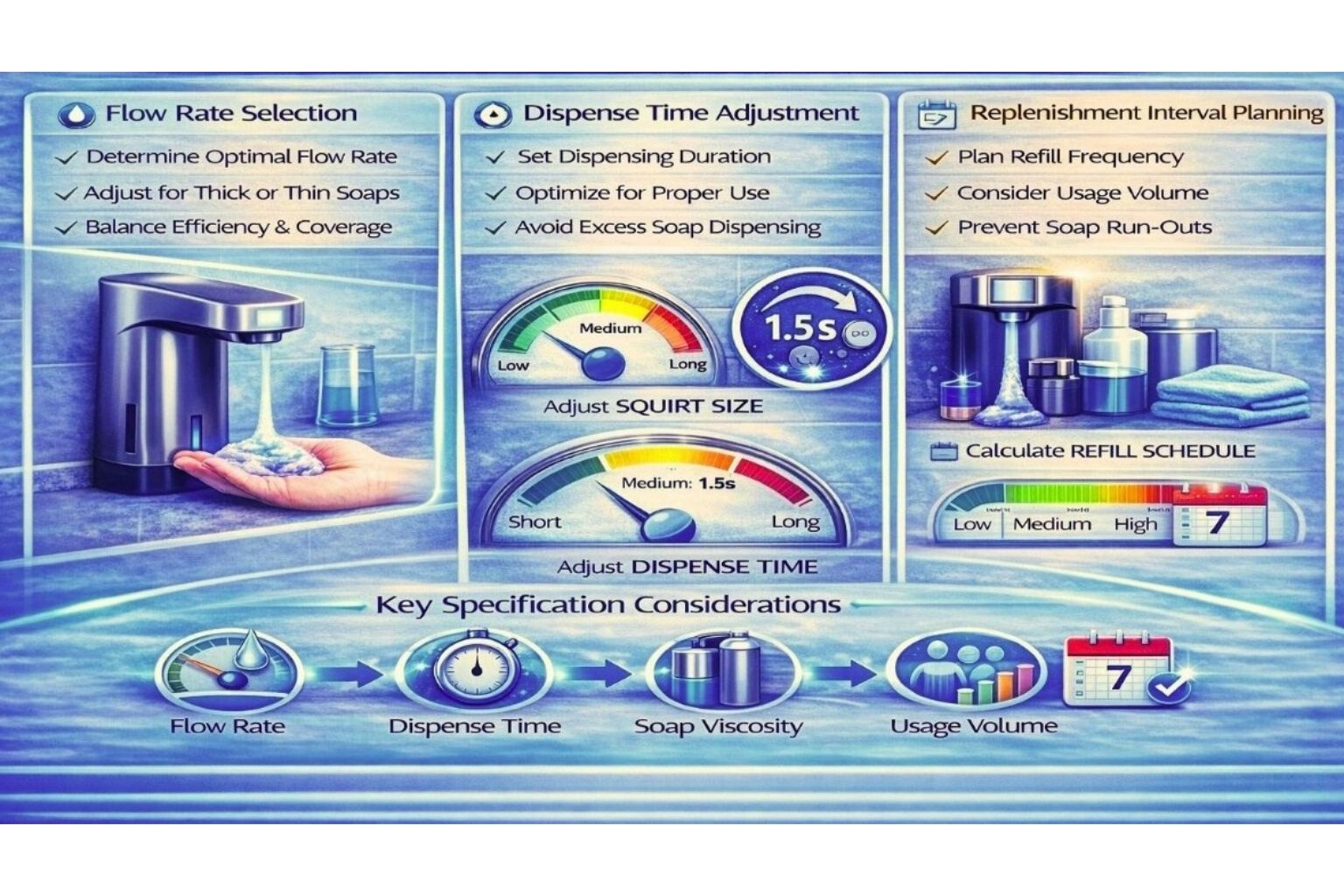

Specifying an automatic soap dispenser is not only about choosing a sensor housing and a finish. In real facilities, the performance outcomes that drive complaints and work orders come down to three measurable settings:

- Dose rate, meaning how much product is delivered per activation

- Dispense time, meaning how long the pump runs per event and how quickly it resets

- Replenishment interval, meaning how long the dispenser stays stocked before refilling is required

When these variables are tuned to traffic level, soap type, and maintenance workflow, dispensers stay reliable, soap stays available, and the sink zone stays cleaner. When they are not, the building sees common problems like over-dispensing, empty dispensers, drips on counters, clogged nozzles, and staff workarounds that reduce hygiene consistency.

Working definition

In this article:

Dose rate means a measurable quantity of soap delivered per activation, typically expressed as milliliters per shot or grams per shot.

Dispense time means the pump run time per activation, plus any lockout or reset time that prevents repeated firing.

Replenishment interval means the time between refills, driven by container capacity, dose size, and number of activations.

Operable parts requirements still apply when there is a manual override or user-operated control. ADA operable parts guidance requires one-hand operation without tight grasping, pinching, or twisting, and no more than 5 pounds of force.

Step 1: Start with the soap format and viscosity

Dose and timing cannot be specified correctly until the soap format is defined.

Foam soap

Foam systems rely on air mixing or foaming formulation behavior. Foam can appear to provide coverage with less liquid mass, but nozzle screens and mixing areas can be more sensitive to dried residue if cleaning is inconsistent.

Liquid soap

Liquid soaps can be simpler in the fluid pathway but vary widely in viscosity. Thick soaps can slow pumping, increase motor strain, and raise the risk of clogging at the nozzle and check valves.

Sanitizer

If the dispenser will be used for alcohol-based hand rub, compatibility becomes a chemical resistance and seal material issue. It also introduces fire code considerations in some locations, especially in healthcare corridors.

Practical specifier action:

- Define foam vs liquid by location and by building type

- Prohibit mixing products in reservoirs

- Require dispenser compatibility with the intended soap type and viscosity range

Step 2: Specify dose rate as a measurable target

Dose rate is the main driver of product consumption, mess, and user satisfaction.

What to capture in the spec and schedule

- Dose per activation, expressed as mL per shot or g per shot

- Whether the dose is fixed or adjustable

- Number of pulses per activation, if the dispenser uses multi-shot logic

Why it matters for AEC teams

- Oversized dose increases cost and causes dripping on decks and floors

- Undersized dose leads users to trigger multiple activations, which often cancels out savings and increases sensor complaints

- A controlled dose improves replenishment predictability for facilities staff

A practical approach in commercial restrooms:

- Use a dose that supports single-cycle handwashing for most users

- Prefer adjustable dose designs where the owner wants tuning after occupancy

- Commission dose settings in a representative restroom after cleaning protocols are in place

Step 3: Specify dispense time and reset behavior

Dispense time is not only pump duration. It includes how the sensor responds to repeated hand presence.

Key variables to define or verify in submittals:

- Pump run time per activation

- Lockout time before the next activation

- Whether the unit supports continuous dispensing if a hand remains present

- Whether nuisance triggers are limited by logic or by sensor zoning

Why dispense time affects performance:

- A long run time increases mess and refills

- A short lockout can cause rapid repeat firing in crowded sink zones

- Poor reset behavior becomes a major complaint in high-traffic restrooms

Commissioning checks that reduce nuisance dispensing:

- Verify activation and reset under real lighting conditions

- Confirm that reflective counters and mirror glare do not cause repeat triggers

- Confirm the dispenser does not fire due to pass-by traffic at sink runs

Step 4: Plan the replenishment interval using a simple calculation

Replenishment interval should be defined by expected use, not guessed.

Basic sizing formula

Replenishment interval in days = (Reservoir capacity in mL) ÷ (Dose per shot in mL × Activations per day)

This allows AEC teams to align dispenser selection with the owner’s staffing model.

Example logic for high-traffic buildings

If a restroom has high turnover and refills are done once per day, choose a capacity and dose setting that avoids mid-day empty conditions.

If refills are done twice per week, size capacity or reduce dose accordingly, or consider a multi-feed system for long sink runs.

Capacity strategy: single units vs multi-feed systems

Single dispenser refills

Single units are simple, but high-traffic facilities can experience frequent refill labor and empty periods if capacities are small.

Multi-feed and top-fill systems

Multi-feed systems can reduce labor by centralizing refills for multiple dispensers.

Bradley describes a top-fill multi-feed soap system that supplies up to six dispensers.

Bradley also notes a 1.3 gallon (5.0 L) tank that can supply up to six soap dispensers or three WashBars.

Why AEC teams use multi-feed:

- One service point for multiple handwashing stations

- Fewer empty dispensers during peaks

- More predictable replenishment interval across a sink run

Coordination requirements:

- Reservoir access must be serviceable without dismantling casework

- Tubing routing and protection must be detailed

- Cleaning protocol must be documented because one contaminated reservoir affects multiple outlets

Hygiene control: refill method affects contamination risk

Dose and timing are not the only performance variables. Refill method can influence hygiene risk if open reservoirs are topped off or tools are shared.

A peer-reviewed study reports that bulk-soap-refillable dispensers are prone to extrinsic bacterial contamination and references findings that roughly one in four dispensers in public restrooms were contaminated in prior studies.

A field study in food service environments discusses microbial detection in open refillable bulk soap and how facility type relates to contamination patterns.

Practical specifier controls:

- Add a no topping off requirement for bulk systems

- Require reservoir cleaning intervals in the closeout package

- Consider sealed refills when staffing turnover is high or hygiene policies are strict

Accessibility and operable parts considerations

Touchless activation reduces the need for manual force, but many units still include:

- Manual override buttons

- Lock access panels

- Push mechanisms in hybrid units

ADA operable parts guidance requires one-hand operation without tight grasping, pinching, or twisting, and no more than 5 pounds of force.

Design coordination tips:

- Ensure any user-operated control is within reach ranges and low-force

- Standardize keys and access so maintenance does not force covers open

- Avoid placing dispensers where they protrude into circulation pinch points

Specification checklist: what to include in the submittal requirements

A) Soap and compatibility

- Soap type: foam or liquid

- Compatibility statement for the intended product type

- Prohibited substitutions and mixing

B) Dose and timing performance

- Dose per activation in measurable units

- Dispense time and lockout behavior

- Any adjustable settings and the adjustment method

C) Capacity and replenishment planning

- Reservoir capacity

- Estimated activations per refill at specified dose

- Target replenishment interval based on anticipated usage

D) Maintenance and closeout

- Cleaning method for nozzle and sensor window

- Spare parts list for valves, nozzles, and seals

- Keying plan and spare keys

- Service access constraints for batteries or power

E) System selection for high traffic

- Consider multi-feed systems for long sink runs and peak demand

- Verify reservoir capacity and number of dispensers served

Example basis-of-design references

ADA operable parts guidance (5 lbf maximum and one-hand operation)

https://www.access-board.gov/ada/guides/chapter-3-operable-parts/

Bulk refill contamination research (peer-reviewed)

https://journals.asm.org/doi/10.1128/AEM.02632-10

Field study on microbial quality in open refillable bulk soap

https://www.sciencedirect.com/science/article/pii/S0362028X22084575

Bradley top-fill multi-feed system (supplies up to six dispensers)

https://www.bradleycorp.com/product/multi-feed-soap-system

https://www.bradleycorp.com/top-fill-multi-feed-soap-system

GOJO LTX dispensing system product data sheet (activation positioning guidance and system behavior)

https://d213yzj61vi89h.cloudfront.net/Bunzl-MLN-Site/attachments/en_US/ProductDataSheet/100147_366395_ProductDataSheet.pdf

Conclusion

Designers can specify soap and dispenser performance when they treat dose rate, dispense time, and replenishment interval as measurable design inputs. Dose affects cost and mess, dispense time affects nuisance activation and usability, and replenishment interval determines whether dispensers stay stocked through peak traffic. The best outcomes come from matching soap format to dispenser design, documenting dose and timing targets, sizing capacity to staffing reality, and selecting refill architectures that the facility can maintain consistently, especially in bulk and multi-feed systems where hygiene protocol matters most.

Supporting References

https://www.access-board.gov/ada/guides/chapter-3-operable-parts/

https://journals.asm.org/doi/10.1128/AEM.02632-10

https://www.sciencedirect.com/science/article/pii/S0362028X22084575

https://www.bradleycorp.com/product/multi-feed-soap-system

https://www.bradleycorp.com/top-fill-multi-feed-soap-system

https://d213yzj61vi89h.cloudfront.net/Bunzl-MLN-Site/attachments/en_US/ProductDataSheet/100147_366395_ProductDataSheet.pdf

No responses yet