For

CommercialSoapDispenserAuto.com

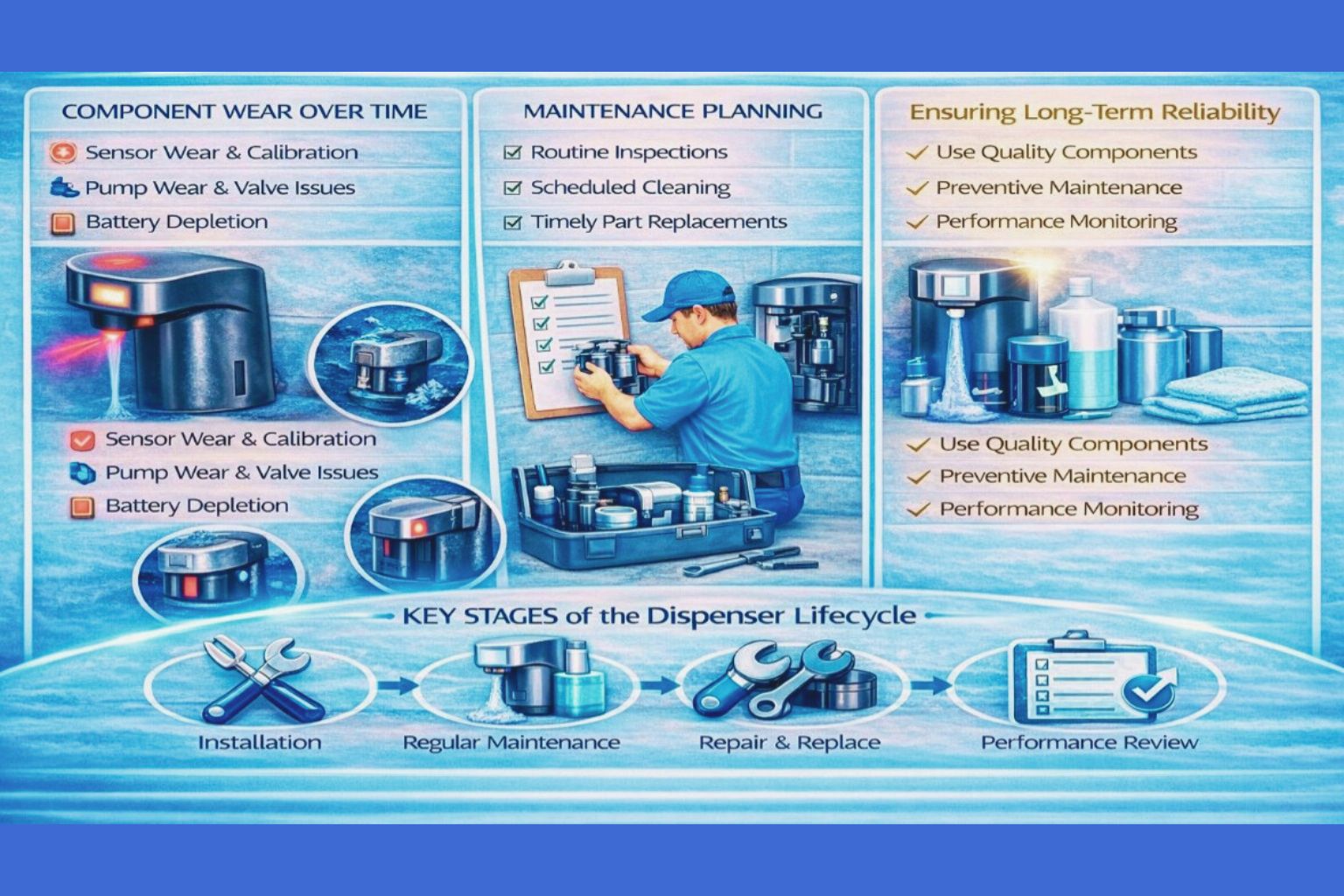

Sensor Soap Dispenser Lifecycle: Component Wear, Reliability & Maintenance Planning

Automatic sensor soap dispensers are often selected to reduce touch points and improve hygiene perception, but their long-term performance is driven by basic lifecycle realities. Pumps wear, sensors get fouled, seals age, and power systems create downtime if access is poorly planned. In high-traffic facilities, the most important question is not how the dispenser looks on day one. It is how many service calls it generates over five years.

For AEC teams, lifecycle planning means choosing dispenser architectures that match traffic level, planning service access, specifying compatible soap, and documenting a preventive maintenance routine that facilities teams can actually follow.

Working definition

In this article:

Lifecycle means the period from installation through years of daily operation, including routine cleaning, refills, parts replacement, and end-of-life replacement.

Reliability means predictable dispensing behavior with minimal nuisance activations, minimal clogging, and minimal downtime due to battery or power issues.

Maintenance planning means defining service access, cleaning steps, preventive inspection intervals, and replacement parts so performance remains stable after turnover from construction to operations.

What actually wears out in a sensor soap dispenser

Most touchless dispensers share a similar architecture. These are the components that typically drive service calls.

1) Sensor window and sensor electronics

Common wear and failure drivers:

- Residue film from soap mist and cleaners on the sensor lens

- Scratches and clouding on plastic lenses from abrasive cleaning

- False triggers in reflective environments or under strong lighting

Planning implications:

- Place dispensers outside primary splash zones

- Ensure the lens can be cleaned without damaging coatings

- Favor designs with stable sensing zones or adjustable settings where applicable

Sensor and serviceability context and field-oriented durability notes:

https://www.fontanashowers.com/benchmarking-touchless-fixture-durability-field-data-fontan-s/11800.htm

https://autotouchlessfaucets.com/reliability/

2) Pump mechanism and dosing pathway

Pump types vary, but typical wear and failure drivers include:

- Thick or incompatible soap causing slow pumping and clogging

- Dried residue buildup in valves and nozzles

- Seal wear and loss of prime over time

- Air intrusion in tubing for multi-feed systems

Manufacturer maintenance guidance commonly notes that soap viscosity and periodic flushing affect long-term operation:

https://thebuilderssupply.com/assets/pdf/bobrick/bobrick-CareAndMaintenanceTB-99.pdf

https://www.webstaurantstore.com/documents/pdf/care_and_maintenance.pdf

3) Check valves, seals, and gaskets

These small parts do a lot of work. Over time, seals can:

- Harden or swell due to chemistry

- Leak at fittings or around reservoirs

- Lose efficiency and increase cycle time

Planning implications:

- Specify soap compatibility and avoid unapproved substitutions

- Include replacement seals and valves in the spare parts package for high-use buildings

4) Power system and battery contacts

In many facilities, the number one avoidable downtime cause is power management:

- Batteries deplete faster than expected in high-traffic restrooms

- Battery compartments are hard to access, leading to delayed replacements

- Contacts corrode or loosen in humid environments

Troubleshooting and service guides show how power indicators and battery changes are central to restoring function:

https://cdnimg.webstaurantstore.com/documents/pdf/ltx_-_troubleshooting_guide.pdf

https://www.youtube.com/watch?v=GmM9cla4qwY

5) Housing, locks, hinges, and mounting hardware

In public restrooms, mechanical wear is not only age related. It is also abuse related.

- Covers loosen from repeated refills

- Hinges fatigue

- Locks fail or keys go missing

- Wall anchors loosen if blocking and substrate are weak

Commercial cleaning and maintenance resource hub for replacement parts and service references:

https://www.bobrick.com/resource-center-2/literature/cleaning-maintenance/

Lifecycle by system type: sealed refills, bulk fill, and multi-feed

Refill design affects reliability because it changes exposure to contamination, residue buildup, and service consistency.

Sealed refill systems

Benefits for lifecycle planning:

- Faster changeouts

- Fewer topping-off related hygiene issues

- More consistent product performance when refills are matched

Service references and manuals for sealed system troubleshooting:

https://cdnimg.webstaurantstore.com/documents/pdf/ltx_-_troubleshooting_guide.pdf

https://www.manualslib.com/brand/gojo/dispenser.html

Bulk fill systems

Lifecycle risks are mostly procedural:

- Topping off without cleaning increases contamination risk

- Mixed soap types change viscosity and residue

- Reservoir film increases clogging and odor complaints

Peer-reviewed evidence on bulk soap dispenser contamination risk:

https://journals.asm.org/doi/10.1128/aem.02632-10

https://www.sciencedirect.com/science/article/pii/S0362028X22084575

Industry operations discussion that highlights the refill pathway as a risk factor:

https://cmmonline.com/articles/danger-in-the-soap-dispenser

Multi-feed systems

Lifecycle advantages:

- One service point for multiple dispensers

- Reduced refill labor on long sink runs

Lifecycle risks:

- If the central reservoir or lines are contaminated, multiple dispensers are affected

- Tubing routing and service access issues create chronic leaks and downtime if not detailed correctly

Multi-feed installation and maintenance manual:

https://www.berls.com/content/site/PDFs/Bradley_Verge_Soap_Multifeed_Manual.pdf

Reliability planning during design: the AEC checklist

1) Design for service access first

If staff cannot service the unit easily, preventive maintenance will not happen.

Design details to confirm:

- Lock access without removing mirrors or panels

- Battery access without awkward reach

- Refill access without disassembling casework

- Space for hands and tools in recessed and deck-mounted conditions

2) Control soap chemistry and viscosity

A large percentage of performance complaints trace back to soap that is too thick, corrosive, or incompatible.

Maintenance bulletins often emphasize that soap quality and viscosity affect long-term reliability and clogging behavior:

https://thebuilderssupply.com/assets/pdf/bobrick/bobrick-CareAndMaintenanceTB-99.pdf

https://www.webstaurantstore.com/documents/pdf/care_and_maintenance.pdf

Spec strategy:

- Define foam vs liquid by location

- Require approved soap types

- Include a change-control note so substitutions require review

3) Commission sensor behavior under real conditions

Commissioning should include more than power-on testing.

Field commissioning tasks:

- Verify activation range at each sink position

- Check for nuisance triggering from pass-by traffic and reflections

- Verify performance under full lighting conditions and daylight conditions where relevant

- Confirm that splash does not foul the sensor window in normal use

Field-oriented reliability protocol reference:

https://autotouchlessfaucets.com/reliability/

4) Plan for vandal exposure where needed

For stadiums, schools, and transit restrooms, include:

- Lock standardization across the building

- Security screw strategy where appropriate

- Reinforced mounting and backing details

Anti-vandal category reference:

https://www.vandalstop.com/vandal-resistant-soap-and-sanitizer-dispensers

Preventive maintenance plan: a practical schedule for commercial restrooms

Facilities teams need a repeatable plan that matches traffic level. The schedule below can be scaled up or down.

Daily or per shift in high traffic sites

- Wipe exterior and nozzle area

- Clean sensor window with a soft cloth

- Check for drips and residue buildup

- Confirm dispenser is operating and not empty

Cleaning and maintenance bulletins that discuss periodic maintenance and flushing:

https://thebuilderssupply.com/assets/pdf/bobrick/bobrick-CareAndMaintenanceTB-99.pdf

https://www.webstaurantstore.com/documents/pdf/care_and_maintenance.pdf

Weekly

- Inspect mounting stability and cover alignment

- Check locks for smooth operation

- Inspect for soap residue at the nozzle tip and around seams

- Verify dose consistency and responsiveness

Monthly or quarterly depending on traffic

- Flush or clean internal pathways if recommended for the model

- Inspect seals and tubing connections for leaks

- Review soap substitutions and ensure compatibility is maintained

- Check battery health or verify power supply stability

Example maintenance manuals and troubleshooting guides used for service routines:

https://cdnimg.webstaurantstore.com/documents/pdf/ltx_-_troubleshooting_guide.pdf

https://www.manualslib.com/manual/2096880/Bobrick-B-850.html

Annual planning

- Replace batteries proactively in battery-heavy portfolios if the facility prefers scheduled replacements

- Refresh spare parts inventory for pumps, valves, and seals

- Review incident logs to identify repeat failure modes by restroom location and lighting conditions

Spare parts and closeout package that reduces downtime

A strong closeout package improves reliability more than most teams expect. Include:

- Model list by room and dispenser type

- Install instructions and maintenance bulletins

- Approved soap list and refill method notes

- Lock key schedule and spare keys

- Spare parts list for nozzles, seals, and pump components

- Commissioning checklist results and sensor range settings

Durability closeout package concept reference:

https://www.fontanashowers.com/benchmarking-touchless-fixture-durability-field-data-fontan-s/11800.htm

Bobrick cleaning and maintenance literature hub for technical bulletins and parts references:

https://www.bobrick.com/resource-center-2/literature/cleaning-maintenance/

Conclusion

A sensor soap dispenser lifecycle is shaped by predictable wear points: sensor lens fouling, pump and valve residue buildup, seal aging, and power management. The most reliable commercial outcomes come from matching refill system type to the facility’s staffing capacity, designing for service access, controlling soap compatibility, and commissioning sensor behavior under real lighting and splash conditions. When preventive maintenance is documented and spare parts are planned upfront, touchless soap systems stay reliable and reduce service burden across the building portfolio.

Supporting References

https://thebuilderssupply.com/assets/pdf/bobrick/bobrick-CareAndMaintenanceTB-99.pdf

https://www.webstaurantstore.com/documents/pdf/care_and_maintenance.pdf

https://www.bobrick.com/resource-center-2/literature/cleaning-maintenance/

https://www.manualslib.com/manual/2096880/Bobrick-B-850.html

https://cdnimg.webstaurantstore.com/documents/pdf/ltx_-_troubleshooting_guide.pdf

https://www.manualslib.com/brand/gojo/dispenser.html

https://www.youtube.com/watch?v=GmM9cla4qwY

https://www.berls.com/content/site/PDFs/Bradley_Verge_Soap_Multifeed_Manual.pdf

https://journals.asm.org/doi/10.1128/aem.02632-10

https://www.sciencedirect.com/science/article/pii/S0362028X22084575

https://cmmonline.com/articles/danger-in-the-soap-dispenser

https://autotouchlessfaucets.com/reliability/

https://www.fontanashowers.com/benchmarking-touchless-fixture-durability-field-data-fontan-s/11800.htm

https://www.vandalstop.com/vandal-resistant-soap-and-sanitizer-dispensers

No responses yet