For

CommercialSoapDispenserAuto.com

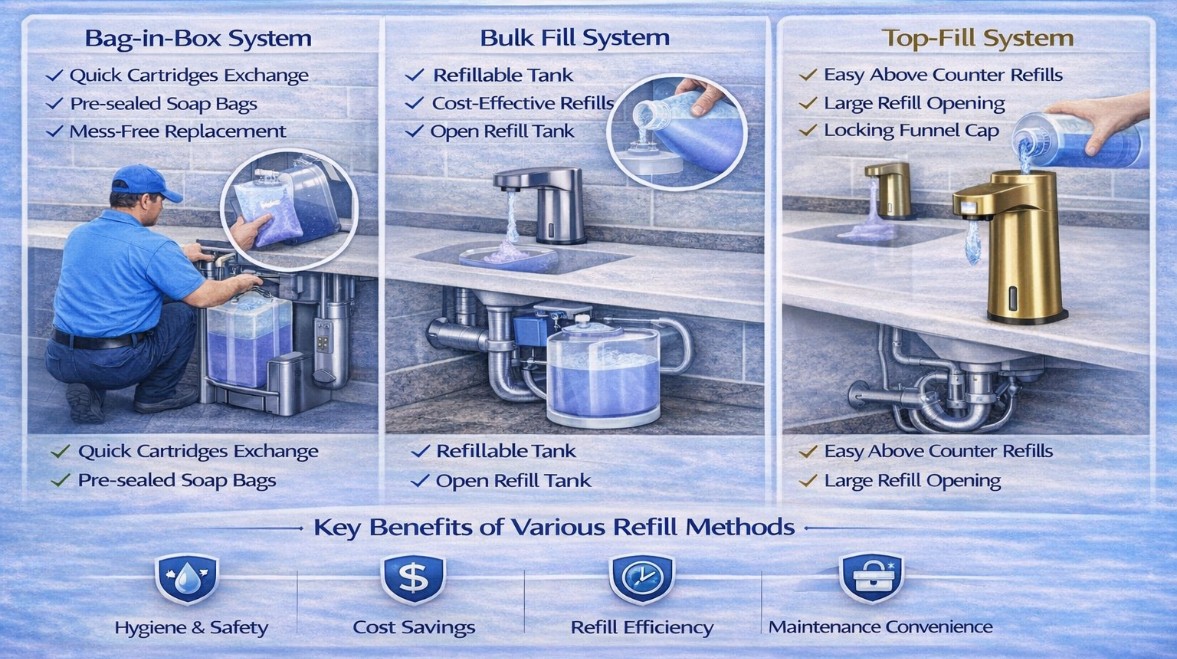

Refill Systems and Cartridges: Bag in Box, Bulk Fill, and Top Fill Dispenser Designs

Refill strategy is one of the biggest drivers of restroom uptime and maintenance cost. Two dispensers can look identical on the wall yet behave very differently over five years depending on the refill method. In high traffic restrooms, refill decisions affect labor time, hygiene risk, storage logistics, and how often a dispenser ends up empty.

For AEC teams, refill system selection should be treated like a performance choice, not just a consumables choice. The refill method determines how the product is protected, how the dose stays consistent, and how easy it is for facilities teams to keep dispensers operating across an entire building.

Working definition

In this article:

Sealed refills means factory sealed cartridges or bags that snap into a dispenser, often with a new nozzle or valve path per refill. GOJO describes its sealed refill approach as reducing contamination risk because the product is factory sealed and includes a fresh nozzle with each refill.

https://d2w0cug36nhzva.cloudfront.net/userfiles/documents/purell_2780-12_specification_sheet.pdf

Bag in box means a soap package inside a rigid box or boxless bag system that feeds the dispenser through a connector.

Bulk fill means a reservoir is refilled from a larger container, usually through a top opening. Some bulk systems are single unit, and some are centralized.

Top fill means the soap is refilled through a dedicated top fill port or reservoir access point. In multi-feed designs, top fill often refers to a central tank that supplies multiple dispensers.

System tiers: sealed refills vs bag in box vs bulk fill and top fill

Sealed cartridge and sealed bag refills

Sealed refills are common in institutional and high traffic buildings because they reduce refill mess, standardize maintenance, and provide predictable product performance.

GOJO TFX dispenser example showing compatibility with 1200 mL refills and ADA compliance notes:

https://www.gojo.com/en/product-catalog/productdetail?sku=2730-12&

Why sealed refills are often specified:

- Faster changeout in the field

- Less product exposure during refill

- Better control of dose and foam quality when using matched refills

- Lower risk from topping off practices

Where sealed refills fit best:

- Healthcare, education, airports, and large building portfolios

- Facilities that want standardized maintenance across sites

- Projects where infection control policies discourage open refills

Support document reference on sealed refills and contamination reduction language:

https://d2w0cug36nhzva.cloudfront.net/userfiles/documents/purell_2780-12_specification_sheet.pdf

Bag in box systems

Bag in box and boxless bag systems are commonly used where facilities want a larger refill volume than small cartridges but still prefer a contained package.

Example bag in box dispenser listing that describes quick refills and bag in box dispensing:

https://www.webstaurantstore.com/kutol-9950zpl-health-guard-soft-silky-800-ml-off-white-bag-in-box-hand-soap-dispenser/5259950ZPL.html

Category context showing bag in box and bottled options grouped as commercial choices:

https://www.katom.com/cat/soap-dispensers.html

Why bag in box is used:

- Larger refill capacity than small cartridges

- More contained than open bulk pour refills

- Often easier to swap than cleaning a bulk reservoir

Where bag in box fits best:

- Food service, retail, and facilities that want higher capacity with simpler logistics

- Medium to high traffic restrooms with predictable soap standardization

Common coordination risks:

- Connector compatibility between soap package and dispenser

- Stocking the correct bag format across multiple buildings

Bulk fill dispensers

Bulk fill systems use a refillable reservoir. They can be low cost to operate, but performance depends heavily on refill practices, cleaning protocols, and soap consistency.

The hygiene risk is not theoretical. A peer reviewed study in Applied and Environmental Microbiology reports that bulk soap refillable dispensers are prone to extrinsic bacterial contamination and references field findings that contamination in public restrooms is common.

https://journals.asm.org/doi/10.1128/aem.02632-10

A practical implication for AEC teams:

- Bulk fill can work, but it requires an operations plan that prevents topping off without cleaning and defines periodic reservoir cleaning.

Industry commentary also highlights contamination concerns in refillable bulk soap dispensers and points readers back to the research literature.

https://cmmonline.com/articles/danger-in-the-soap-dispenser

Where bulk fill fits best:

- Facilities with strong janitorial training and consistent procedures

- Projects where consumable cost is a dominant driver and protocols are enforceable

Where bulk fill is risky:

- High turnover staff environments with inconsistent procedures

- Locations where dispensers are frequently topped off without cleaning

Top fill and multi-feed top fill systems

Top fill can refer to a single dispenser design or a central reservoir that feeds multiple dispensers.

Bradley describes its top fill multi-feed system as supplying up to six dispensers with foam or liquid soap for high traffic multiple station conditions.

https://www.bradleycorp.com/product/multi-feed-soap-system

ASI describes a top fill multi-feed kit using a single reservoir to refill up to six dispensers with one pour and notes a 6 L reservoir capacity.

https://americanspecialties.com/product/ez-fill-top-fill-multi-feed-kit-0390/

Why top fill multi-feed is specified:

- One service point for multiple dispensers

- Reduced labor in long sink runs

- More consistent soap availability across a restroom core

Where top fill multi-feed fits best:

- Airports, stadiums, campuses, convention centers

- Projects with long sink runs and dedicated maintenance staff

Common coordination risks:

- Tubing routing and protection inside casework

- Access to reservoir and controls without removing panels

- Commissioning to ensure consistent dose at every dispenser

Technical differences that matter to AEC teams

Hygiene and contamination control

Sealed refills reduce exposure during replacement and avoid topping off. GOJO sealed refill documentation highlights reduced contamination risk because the product is factory sealed and includes a fresh nozzle with each refill.

https://d2w0cug36nhzva.cloudfront.net/userfiles/documents/purell_2780-12_specification_sheet.pdf

Bulk refill systems require a cleaning protocol. Research shows bulk soap refillable dispensers can become contaminated when refill practices are poor.

https://journals.asm.org/doi/10.1128/aem.02632-10

Maintenance time and labor

Sealed refills: fastest changeout, minimal mess.

Bag in box: moderate changeout time, larger volume.

Bulk fill: refill can be fast but requires periodic cleaning and strong training.

Top fill multi-feed: fastest service per sink run once installed, but more coordination in design.

Dose consistency and performance

Sealed systems generally deliver more consistent foam and dose when refills are matched to the dispenser.

Bulk and multi-feed systems can perform well, but dosing consistency depends on:

- Soap viscosity and compatibility

- Pump design and priming behavior

- Cleaning of valves and nozzles

- Avoiding air intrusion in lines for multi-feed systems

Storage and procurement logistics

Sealed refills can simplify ordering because SKU control is tight. The downside is vendor lock-in.

Bag in box can reduce packaging volume and increase capacity per changeout but requires consistent package compatibility.

Bulk fill can reduce consumable packaging but increases the importance of managing soap standardization and training.

Total cost of ownership over five years

The least expensive refill per ounce is not always the lowest cost in the building.

Cost drivers that often dominate:

- Labor time to service dispensers

- Frequency of empty dispensers and complaint-driven calls

- Contamination and cleaning incidents in bulk systems

- Parts replacement from clogs and dried residue

- Inventory complexity across campuses

Typical outcomes by system:

- Sealed refills often cost more per unit of product but reduce labor and hygiene risk

- Bag in box can balance higher capacity with controlled replacement

- Bulk fill can be low cost if procedures are consistent, but failures can be expensive

- Top fill multi-feed can reduce labor significantly in long sink runs when designed and maintained correctly

When to specify each refill approach

Specify sealed refills when

- Healthcare, education, and institutional hygiene expectations are high

- Maintenance teams need fast and consistent changeouts

- The owner wants clear documentation and standardized consumables

Reference examples:

https://www.gojo.com/en/product-catalog/productdetail?sku=2730-12&

https://d2w0cug36nhzva.cloudfront.net/userfiles/documents/purell_2780-12_specification_sheet.pdf

Specify bag in box when

- You want larger capacity than small cartridges

- The facility prefers contained packages rather than open pouring

- The owner can standardize packages across sites

References:

https://www.webstaurantstore.com/kutol-9950zpl-health-guard-soft-silky-800-ml-off-white-bag-in-box-hand-soap-dispenser/5259950ZPL.html

https://www.katom.com/cat/soap-dispensers.html

Specify bulk fill when

- The facility has disciplined refill and cleaning protocols

- Consumable cost is a top priority

- The owner is prepared to document and enforce procedures

Evidence reference:

https://journals.asm.org/doi/10.1128/aem.02632-10

Specify top fill multi-feed when

- There are long sink runs and high traffic periods

- Maintenance labor reduction is a major goal

- Casework and tubing coordination can be detailed properly

References:

https://www.bradleycorp.com/product/multi-feed-soap-system

https://americanspecialties.com/product/ez-fill-top-fill-multi-feed-kit-0390/

Example basis of design references

Sealed refill and dispenser system references

https://www.gojo.com/en/product-catalog/productdetail?sku=2730-12&

https://d2w0cug36nhzva.cloudfront.net/userfiles/documents/purell_2780-12_specification_sheet.pdf

Top fill and multi-feed systems

https://www.bradleycorp.com/product/multi-feed-soap-system

https://americanspecialties.com/product/ez-fill-top-fill-multi-feed-kit-0390/

Bag in box system examples and category context

https://www.webstaurantstore.com/kutol-9950zpl-health-guard-soft-silky-800-ml-off-white-bag-in-box-hand-soap-dispenser/5259950ZPL.html

https://www.katom.com/cat/soap-dispensers.html

Peer reviewed contamination research and hygiene discussion

https://journals.asm.org/doi/10.1128/aem.02632-10

https://cmmonline.com/articles/danger-in-the-soap-dispenser

Conclusion

Refill systems drive real performance in commercial automatic soap dispensers. Sealed refills support fast maintenance and contamination control. Bag in box systems offer higher capacity in a contained package. Bulk-fill systems can lower costs, but they require disciplined cleaning and refilling, while top-fill multi-feed designs reduce labor in high-traffic sink runs when teams properly coordinate reservoir locations, tubing paths, and service access.

For AEC teams, the strongest approach is to select the refill method based on traffic level, maintenance capacity, hygiene policy, and how standardized the owner wants consumables to be across the facility.

Supporting References

https://www.gojo.com/en/product-catalog/productdetail?sku=2730-12&

https://d2w0cug36nhzva.cloudfront.net/userfiles/documents/purell_2780-12_specification_sheet.pdf

https://www.webstaurantstore.com/kutol-9950zpl-health-guard-soft-silky-800-ml-off-white-bag-in-box-hand-soap-dispenser/5259950ZPL.html

https://www.katom.com/cat/soap-dispensers.html

https://www.bradleycorp.com/product/multi-feed-soap-system

https://americanspecialties.com/product/ez-fill-top-fill-multi-feed-kit-0390/

https://journals.asm.org/doi/10.1128/aem.02632-10

https://cmmonline.com/articles/danger-in-the-soap-dispenser

No responses yet