Industrial Trends: Commercial Automatic Touchless Soap Dispensers

A technical AEC-focused analysis of how automatic touchless soap dispensers impact hygiene performance, smart-building integration, lifecycle cost, and specification practice in modern commercial washrooms.

In the AEC (architecture, engineering, construction) sector, commercial washrooms have shifted from functional, afterthought spaces to mission-critical hygiene zones that influence health outcomes, user experience, and facility lifecycle performance. As a result, commercial automatic touchless soap dispensers have become a core component of modern restroom programming, specification, and compliance.

This article outlines current industrial trends shaping these devices from an AEC-grade technical perspective, covering hygiene drivers, connected technology, material durability, sustainability, and specification criteria, supported by verifiable research sources. All sources appear as hoverable buttons that open in new tabs.

Market signals and hygiene priorities

The worldwide market for touchless soap dispensers is expanding consistently. Market researchers report a 2024 global market valuation of approximately USD 0.26 billion, with a projection to reach approximately USD 0.68 billion by 2033, representing a compound annual growth rate near 11.3 percent over the forecast period.

The surge in adoption is driven by several converging needs in commercial environments. There is a clear requirement to reduce cross-contamination through touch-free fixtures. Facility owners and operators also seek improved compliance with hygiene and infection-control standards, streamlined maintenance workflows for high-traffic washrooms, and a shift toward smart restroom ecosystems where dispensers, faucets, dryers, and occupancy sensors operate as a coordinated system.

For AEC professionals, this behavior translates to treating touchless soap dispensers as essential fixtures rather than optional accessories. The devices are particularly critical in healthcare, hospitality, retail, food service, transit hubs, airports, and educational facilities where throughput, accreditation, and experience metrics are tightly managed.

Performance, connectivity, and fluid control

Touch-free soap dispenser designs are continuing improvements when it comes to accuracy, robustness, and integration. In terms of AEC, the most applicable ongoing development trends would be categorized into three: advances in sensors, connectivity within smart buildings, and fluid control optimization.

Sensor advancements

Many current units deploy infrared, radar, or hybrid sensors that minimize missed activations and false triggers. Response latency is shrinking below three-tenths of a second in numerous commercial-grade models, helping to keep user experience smooth and predictable. Multi-spectrum sensing approaches also improve performance under challenging conditions such as bright lighting, steam, or reflective surfaces.

Smart building connectivity

Connectivity and data capture are increasingly standard. Common capabilities include usage tracking that supports preventive maintenance, refill-level alerts routed to computerized maintenance management systems and building management systems, logging of dispense counts for hygiene reporting, and predictive analytics built from observed user flow patterns. These features allow soap dispensers to contribute directly to facility management dashboards.

Fluid control and efficiency

Fluid control hardware is also improving. Many dispensers now support adjustable dosing ranges in the half-milliliter to two-milliliter band, with valve configurations that can be tuned for either foam or liquid product. Pump modules are often rated for one hundred thousand to two hundred thousand cycles, which aligns well with high-traffic commercial deployment.

In combination, these developments help AEC specifying teams rely on consistent performance in busy zones while still aligning fixtures with sustainability and maintenance objectives.

High-volume sectors and design timing

Market data indicates that commercial sectors now dominate installation volumes for automatic touchless soap dispensers, representing well over sixty percent of deployments. The healthcare community utilizes these fixtures as part of a serious infection control program. Hospitality companies include the fixtures as a means of promoting guest perceptions and hygiene scores. The office settings incorporate health spaces as part of overall wellness initiatives.

Transportation hubs, such as airports or large transit points, use touch-free dispensers because of the need to process a high volume of traffic and sanitize the equipment regularly. Educational institutions tend to focus on cost-effective, vandalism-resistant hand sanitizers suitable for regular usage.

For architects and engineers, the trend sustains the importance of kicking off dispenser specification in design development instead of leaving the decision to procurement late in the process. Soap dispensers shape wall rough-ins, mounting plates, wiring and power planning, maintenance clearance, and even flow patterns within the vicinity surrounding the hand-washing area.

Resource efficiency and long-term operation

Key sustainability trends

Sustainability imperatives now influence both product design and specification language. Larger refill capacities in the range of one thousand to fifteen hundred milliliters reduce maintenance frequency and site labor. Refillable cartridge formats help reduce plastic waste by avoiding single-use containers. Stainless steel housings in grades three hundred four or three hundred sixteen support long service life and recyclability at end of use.

Many systems also use low-waste dosing strategies. Foam-based dispensing can reduce soap consumption by roughly forty to seventy percent compared with traditional liquid dosing, which materially impacts operating cost and waste generation.

Lifecycle considerations

A well-selected dispenser reduces total cost of ownership. Lower soap usage lowers recurring consumable expense. Predictive maintenance capabilities minimize downtime and user complaints. Connected devices reduce unnecessary labor hours by focusing staff only where refill or servicing is actually required. Robust housings and internal components extend the replacement cycle and reduce waste from premature failure.

For AEC teams drafting Section 10 28 00 Toilet Accessories specifications, lifecycle assessment should appear alongside functional and aesthetic criteria to align with owner sustainability goals.

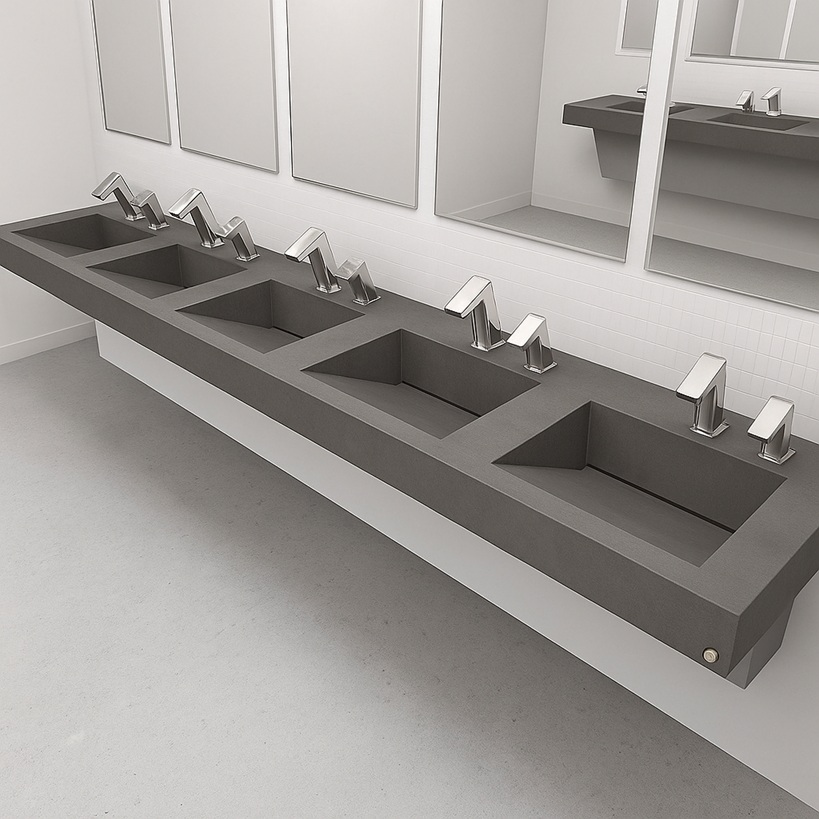

Aligning fixtures with AEC aesthetics and coordination

Restroom design trends favor cohesion, minimalism, and reduced visual clutter. Touchless dispensers follow this direction through slim wall-mounted and deck-mounted profiles, coordinated finish options such as brushed nickel, matte black, stainless, and PVD colors, and recessed niches that improve tamper resistance and clean sightlines. Many product families now integrate with mirror systems and faucet lines to create a unified visual language.

Architects are encouraged to coordinate dispenser placement with accessibility reach ranges, circulation paths in front of the handwashing zone, mirror and faucet alignment, and service access routes behind or below the fixtures. Sensor performance can also be impacted by nearby reflective metals or intense directed lighting, so sensor interference zones should be considered in coordination meetings.

Key content for Section 10 28 00 Toilet Accessories

A complete technical specification for a commercial touchless soap dispenser should capture functional behavior, performance metrics, materials, installation conditions, smart integration, compliance references, and warranty expectations. The following structure aligns with MasterFormat conventions while staying practical for project teams.

From fixtures to data-generating infrastructure

Over the next five to seven years, a combination of developments will rewrite the rules for AEC teams who specify touchless soap dispensers. IoT-native models will become the norm for larger facilities. Machine-learning models will be able to predict demand for refills and service, based on observed usage. High-efficiency foam-generation systems will further decrease chemical and water waste.

Modularity, for instance, will be used to help extend product lifetimes via sensor technology upgrades without the need for full housing replacement. Antimicrobial alloys and surface treatments will be in wider use within high-risk environments. Many projects will move toward fully integrated touchless ecosystems that link faucet, soap, dryer, and occupancy sensing into unified systems that inform building analytics.

As these changes take hold, dispensers will no longer be treated as isolated accessories. They will function as instruments feeding real-time data into digital facility twins, capital planning models, and ESG reporting frameworks.

Conclusion

Touchless automatic dispensers for commercial use are now essential elements of hygiene strategies in buildings. They presently interact with and benefit AEC, facility management, and interior design practices. Enhancements made with regards to the sensing mechanism, connectability, robustness, and sustainability enable touchless automatic dispensers to make a direct contribution to increased efficiency, health, and sustainability.

As far as architects, engineers, and specifiers are concerned, early coordination and technical documentation are also crucial. If dispensers are incorporated into programming, detailing, and specification at the right point in time, commercial washrooms are able to provide performance and value.